Examining the Small, Medium, and Large of Preventing Automotive Latent Defects

White Paper

One known risk to automotive electronics is latent defects; failures that do not show up in testing at the semiconductor fab or in subsequent burn-in testing of a component package. These defects can develop over time leading to failures that can result in safety hazards and expensive recalls.

Today, modern vehicles have:

- 100 thousand lines of digital code, a number predicted to rise six-fold by 2025,

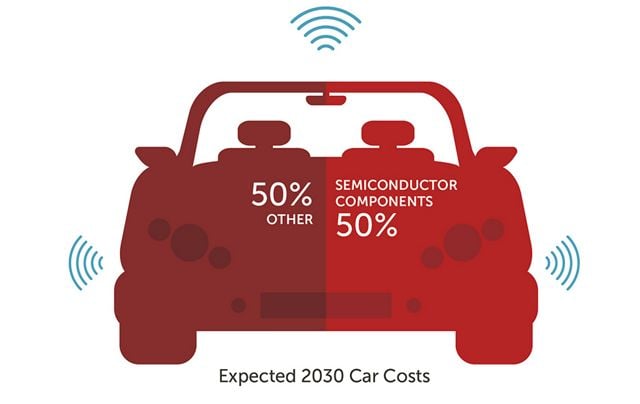

- By 2030, electric and autonomous vehicles are projected to have about half their value in onboard electronics

- Over thirty percent of today’s field failures are attributable to a vehicle’s electronics

This white paper details the challenges facing automotive OEMs, semiconductor fabs, and tier one suppliers and identifies solutions for improving the cleanliness of the chemistries, gases, air, and wafers used to create microchips of all types: analog, digital, and mixed signal.