A New Collaborative Approach to Defectivity Challenges in the Automotive Industry

How to support the industry to reach zero defects

The automotive industry is in a transformation phase: 80% of the innovation will come from the semiconductor industry. By 2030, 50% of the automotive costs are expected to be in the electronics that enable driver assistance and automation technologies. Reaching new levels of automotive innovation poses a new challenge to the industry–achieving the ppb failure rate at the component level.

The solution is in collaboration.

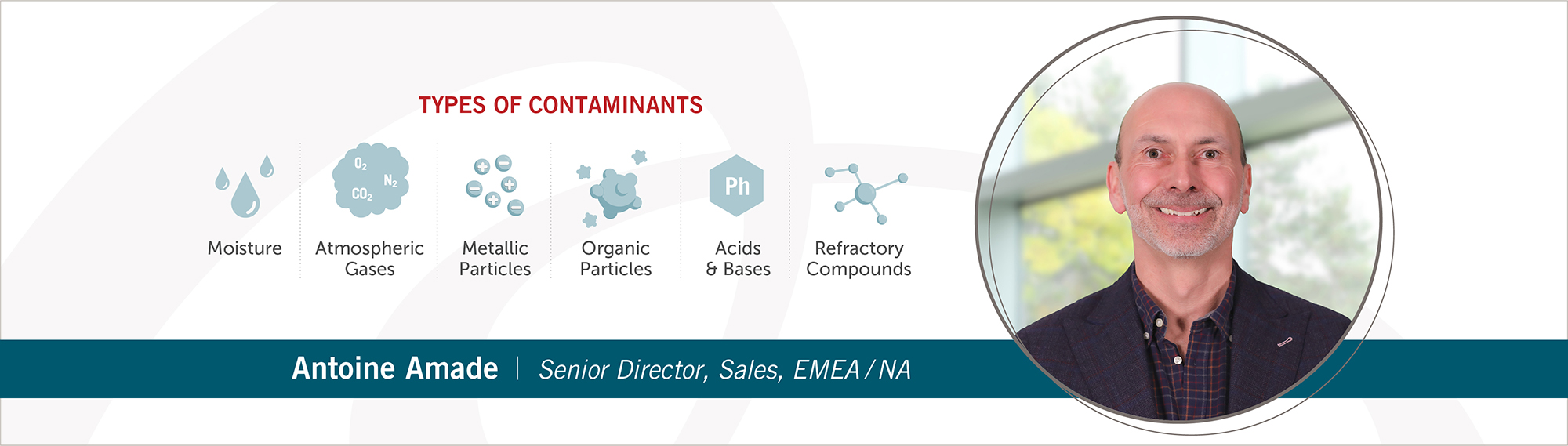

Material purity and performance will play a key role in reducing latent defects. Non-visible “black box” contamination, which can be missed by the installed metrology tools, has the potential to negatively impact semiconductor chip reliability later in the life of the automobile. If the industry wants to reach “zero defects,” a new collaborative approach is necessary

register to hear about:

- The challenges of the automotive industry

- Latent defects and their impact on the ecosystem

- A good contamination control strategy

- A new model of engagement to reach the ppb level defectivity

About THE Presenter:

Mr. Amade joined Entegris in 1995 as an application engineer in its semiconductor business. Today, he is the EMEA/NA senior director focused primarily on growing the semiconductor business in Europe and the Middle East through market strategies and the management of sales, customer service, and marketing teams. For nearly 25 years, Mr. Amade has held leadership positions at Entegris in gas microcontamination market management, strategic account management, and regional sales management. Mr. Amade has a degree in Chemical Engineering from ENS Chimie Lille and is a member of the SEMI Electronic Materials Group and the Global Automotive Advisory Council for Europe (GAAC).

Mr. Amade joined Entegris in 1995 as an application engineer in its semiconductor business. Today, he is the EMEA/NA senior director focused primarily on growing the semiconductor business in Europe and the Middle East through market strategies and the management of sales, customer service, and marketing teams. For nearly 25 years, Mr. Amade has held leadership positions at Entegris in gas microcontamination market management, strategic account management, and regional sales management. Mr. Amade has a degree in Chemical Engineering from ENS Chimie Lille and is a member of the SEMI Electronic Materials Group and the Global Automotive Advisory Council for Europe (GAAC).